-

More information

-

1. Aims and Objectives 2. Summary

3. Process of Anaerobic Digestion 4. Key Features of working with RAW

5. Process and Timing 6. RAW Biogas

7. Technical Partner 8. Bio-methane

9. Design, Build and Area 10. Site access and vehicle reception

11. Digestate storage 12. Grid connection

13. Planning permission 14. Access to feedstock

15. Crop yield information 16. Operation and Lease

17. Output quantification and utilization 18. Financial benefits explained

1. Aims and Objectives

The aim of an AD (Anaerobic Digestion) plant developed by RAW Biogas is to produce a sustainable supply of bio-‐methane into the mains grid with the minimum of environmental impact. These developments reduce the UK’s reliance on fossil fuel gasses, including those which have been sourced through Import or fracking. The feedstock comprises of processed food or drink waste and agricultural waste. The digestate generated by the plant can be used on local farms to improve the efficiency of crop production. Digestate features significantly improved nitrogen accessibility for plants when compared to farm yard manure (FYM). The objective is to have a productive AD plant, which is financially encouraged by the Government through the RHI scheme, for at least 20 years. This is based on their need to reach the UK’s 2020 target of 10% of all gas used being from renewable sources.

2. Summary

A RAW Biogas Gas to Grid project is underpinned by the following assumptions:

1. Planning consent is granted for an anaerobic digestion plant with a total annual capacity of at least 40,000 tonnes of waste and agricultural feedstock.

2. Sufficient land is available for the digesters, storage/clamps, digestate lagoons, access, gas harnessing and processing equipment, and all associated infrastructure. This will amount to up to 8 acres depending on feedstock storage requirement.

3. A landowner is willing to assist RAW Biogas to ensure that a sufficient supply of feedstock is provided throughout the year. This is essential for allowing the plant to continuously operate at maximum capacity, thereby maintaining its projected revenues.

4. There is a suitable connection to the gas transmission grid or local use, where sufficient capacity is available to take the total quantity of gas produced by the plant whilst running at maximum permitted capacity. An adequate pressure pipeline is required to be within a specified maximum distance for the scheme to remain financially viable.

5. RAW Biogas will provide the expertise required for obtaining the necessary consents, agreements and funding in order to construct and operate the plant.

6. RAW Biogas will appoint an experienced contractor and technology provider who will work with us during the design, installation, commissioning, and operation of the project.

7. RAW Biogas will oversee the daily operation of the plant in conjunction with the plant manufacturer, O&M teams (Operations and Maintenance) and, depending on their desire for involvement and ability, the landowner.

8. On average the plant will inject 450scmh (Standard Cubic Metres per Hour) of upgraded bio-‐methane into the gas user or national high pressure gas grid. This equates to approximately 42,000MWh (megawatt per hour) of exported energy per annum.

9. The project must produce gas with a purity of at least 97% CH4 (Methane) for its production to meet the required standards for the UK gas grid network.

10. The plant will operate for a minimum of 20 years to maximise the subsidies available.

11. All parties will cooperate to safeguard the quality and supply of feedstock for the duration of the project whilst continuously looking for opportunities that might enhance the revenue of the plant or extensions to the plant.

3. The Process of Anaerobic Digestion

AD (Anaerobic Digestion) is a naturally occurring process involving the breakdown of organic matter into carbon dioxide, methane and water by two groups of microorganisms called bacteria and archaea. The reaction occurs in a sealed tank or digester whereby the absence of oxygen provides the ideal environment for these microorganisms to thrive. There are four stages to the anaerobic digestion process which will take place in a RAW biogas Gas to Grid project. It will take between six and eight weeks to complete an entire cycle and includes:

1. Hydrolysis -‐ The breakdown of complex organic matter such as carbohydrates, fats and proteins.

2. Acidogenesis -‐ The breakdown of sugar molecules, fatty acids and amino acids.

3. Acentogenesis -‐ The conversion of fatty acids and alcohols into hydrogen, carbon dioxide and acetic acid.

4. Methanogenesis -‐ The conversion of any remaining hydrogen and acetic acid into methane and carbon dioxide.

By the end of the fourth stage, all of the practically accessible biogas has been removed from the feedstock material. This methane gas is then scrubbed to remove the carbon dioxide and other impurities from it. The calorific content will be analysed and propane is added accordingly to maintain consistency. It is then pressurised to the equivalent of the djoining gas pipeline and injected into the grid. The resulting digestate is subsequently removed and stored then finally applied to local farms.

4. Key Features of working with RAW Biogas

• We develop Gas AD systems or combined heat and power AD systems. This is primarily because gas burned at power plant level, or transported through the network directly to domestic and commercial consumers, is a more efficient process than can be achieved by an on-‐site generator. On sites generators with a suitable grid connection will often include a Combined Heat and Power (CHP) unit to increase the overall plant efficiency.

• We have an experienced team, with a diverse skill set, to provide the expertise required for developing projects from inception, through delivery, and into operation. This ensures continuity throughout the project lifetime.

• We have a highly regarded asset management division which will be the primary point of contact for the whole term of the lease, regardless of the projects specific ownership.

• We always ensure the biogas produced from the AD plant is carefully upgraded to bio-‐methane on-‐site to maximise supply and value, and avoid any gas quality issues.

• The asset management division of RAW Energy will manage the sale of gas and the RHI (Renewable Heat Incentive) to make sure that the project is, at all times, maximising the value of subsidies available.

• We only work with EPC (Engineering, Procurement and Construction) technology partners who are able to deliver a turnkey solution for the plant to avoid any issues with compatibility. These partners have all successfully built projects in the UK.

• We visit sites built by various technology providers to ensure that we understand the merits of each technology and to build strong relationships with the technical personnel.

• We have a £75m framework agreement in place with our funding partners for the development and financing of eight schemes. They will provide the capex for this tranche of projects to be fully developed, constructed and commissioned.

• We only work with the leading gas grid connection experts who ensure technical excellence and compliance throughout.

• We have our own in-‐house legal partners and are able to offer very fast document turnaround.

• We have a dedicated planning resource to ensure that we remain close to all nuances of each projects development. This ensures that challenges are attended to quickly and comprehensively.

• We draft a complete feedstock ‘menu’ for each site depending on location and quality of surrounding farmland, and negotiate and agree all feedstock agreements. We would, of course, be very keen to procure as much feedstock as possible from the site provider.

5. Process and Timing

Our usual process and timings for a successful scheme are as follows. These are important to adhere to as historically Government subsidy rates for renewable energy tariffs quickly decrease. The RHI, in the case of Gas to Grid AD, decreases quarterly.

Week 1- Receive land ownership maps and conduct complete desk top analysis outlining potential for scheme including site selection, initial planning and gas connection investigation.

Week 2- Decide if land has potential for development. If so then send out Heads of Terms to landowner and agent. If the land is not suitable for a biogas plant RAW will also review the land for other renewable development opportunities.

Week 3-4 - Agree Heads of Terms.

Week 4-5 - Sign and exchange Heads of Terms.

Week 5-9 - Our lawyers will send across undertaking and Option and Lease agreements.

Week 9-10 - Sign Option with appended Lease.

Week 10‐12 ‐ Hold public consultation and draft planning documents.

Week 12‐13 ‐ Submit planning application.

Week 13‐27 ‐ Respond where required on the LPA (Local Planning Authority) enquiries and conduct surveys where required. Sign letters of intent for feedstock providers.

Week 27‐30 ‐ Planning consented.

Week 30‐34 ‐ Conditions discharged where applicable and complete due diligence.

Week 34‐40 ‐ Sign feedstock agreements, EPC contracts and Gas Grid connection documents.

6. RAW Biogas

RAW Biogas is a subsidiary of the RAW group of companies whose activities involve financial planning and management, consultancy, planning applications, development and project management in AD plants, biomass projects and solar PV schemes.The co-location of these activities on a single site enables RAW Biogas to capitalise on financial knowledge and project management of the AD site. RAW Biogas is involved specifically with AD plants and has the ability to create planning applications as well as manage a site through to its end of life in 20 plus years. RAW Biogas has strong motivations to provide a complete service to every customer. This includes planning, financial management, project development with investment structuring, gas purchase agreements, operation and maintenance contracts and monitoring the system.

7. Technical Partner

RAW Biogas work with a selection of tier 1 technical partners and will be selecting the most appropriate contractors for each site. All partners have many years of experience and build world class, highly efficient, profitable and reliable systems. The technical partner will provide information concerning their requirements for design and construction of each biogas plant. We will then use this information for the consent process and oversee the construction phase with them throughout. RAW will also monitor ongoing technical and biological matters to ensure that every plant is working to its maximum efficiency.

8. Bio‐methane gas and why it is so important

Bio‐methane is a naturally occurring gas which is produced commercially by the anaerobic digestion of organic matter such as dead animal and plant material, manure, sewage, organic waste, etc. Chemically, it is identical to natural gas. However, bio-‐methane gas is not classed as a fossil fuel because it is produced from ‘fresh’ organic matter. The important difference is that the carbon released when the gas is burned has been stored over a short period of time, as the plants have absorbed carbon during their lives of less than a year. This is different to fossil gas which contains compounded carbon, stored potentially over thousands of years. Bio‐methane can be used locally or fed directly into the gas network and used in the same way as natural gas. Using bio‐methane makes our gas supply less carbon-intensive than using imported natural gas. This can help the UK Government’s 2020 commitment to meet 15 per cent of final energy demand from renewables, and reduce UK carbon emissions by 34 per cent. The bene its of bio‐methane gas are that it helps to meet greenhouse gas and waste reduction targets. It contributes to securing a percentage of renewable energy supply. There are also cost effective connections with the gas distribution network, reaching over 80 per cent of UK homes with no need to change existing appliances, thus avoiding the disruption associated with replacing them. These are all clear reasons why it is essential to invest in AD plants for the future supply of energy.

9. Design, build and area required

The construction of a RAW Biogas AD plant begins with technical surveys including geophysical and geotechnical evaluation to understand topography, soil composition and substrate. The site layout will then be georeferenced for the location of main structures. The first element of construction involves the improvement and installation of the main access point to allow easy access for the construction phase and the relatively modest flow of traffic post build. Large earthmoving equipment will then be brought on site to dig the foundations and remove soil to create a level working area and occasionally lower the setting in the landscape in order to reduce the visual impact. The site will consist of the main digesters, feedstock storage/clamps, feedstock acceptance tanks, upgrading equipment, digestate lagoons, weighbridge, office and control center buildings, CHP generator, safety flare and pressurization equipment. It will encompass up to eight acres, depending on the topography and shape of site.

10. Site Access and Vehicle Reception

All sites with the potential for development require an adequate access point which connects the unit to the public highway. On site there will be a large, concrete based vehicle reception area. Sensitivity modelling will be undertaken as part of the initial planning application, allowing for the vehicle load on route to increase by at least 50% without detrimental impact to the site or local network.

11. Digestate Storage

Digestate storage is an essential part of an anaerobic digestion plant. This is a bi-‐product of the AD process. The digestate requires a storage lagoon or digestate bags to be located alongside the AD development. These need to be capable of containing 10,000 m3 of material. This will be included in the planning application through RAW Biogas.

12. Grid Connections

If the bio-‐methane is not all used locally then the sites may need to be in relatively close proximity to a gas transmission pipeline in order for them to be a viable contributor to the national gas grid. Construction on site will be needed to install gas upgrading equipment and a pressurisation unit to make the gas suitable for the grid. The scheme will require a low power connection to the electricity grid for the general operation of the site.

13. Planning Permission

Permission details-

Planning permission will be sought from the local authority planning office and the landowner will be required to help in any way required to facilitate the grant of consent. Depending on the requirements of the local planning authority, there will be a series of reports commissioned to support the planning application. These reports could include Environmental Impact Assessment, traffic movements, construction access, visual impact, odour assessment, etc. Generally, our planning partner will engage the local planners in a pre-application to understand the local influences and adapt the application to fit. If the consent is not granted then RAW biogas retains the right to go to appeal.

Permission Conditions-

Often, the granting of planning consent comes with a series of conditions. These can vary from the colours of equipment to environmental protection plans. RAW Biogas will ensure all of the conditions are met while constructing and operating the plant and any pre-commencement conditions are dealt with prior to any construction work on site.

14. Access to Feedstock

In the spirit of minimising vehicle movements, RAW Biogas strives to collect the total feedstock required for the site from the smallest possible area. Ideally, all the feedstock input providers are within close proximity of the site. The greater quantity of feedstock either supplied from the landowner of the plant, or arranged company, the better the scheme will work for all the parties involved. It is essential for AD plants to have a high output feedstock crop. Ideally, the biogas production would benefit from a consistent mix of feedstock materials, chopped and blended to ensure optimum methane yield. Yield is the overriding consideration for efficient production. The digestion rate of different feedstocks within a biodigester varies from two days to two months. The sugar content is the main factor that alters the ferment time. RAW will manage all feedstock agreements, feedstock quantity breakdown, and digestate management.

15. Yield Information

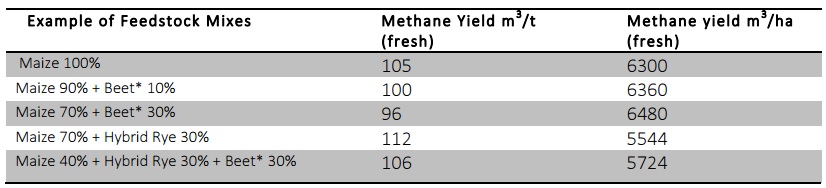

The yield of the feedstock will impact the productivity of the AD plant. This is why it is essential to get the correct mixture in to the AD plant and a rotational mix. Below shows an example of different crop based feedstock mixes and their methane yields.

*assumes ensiled beet, KWS Bioenergy.

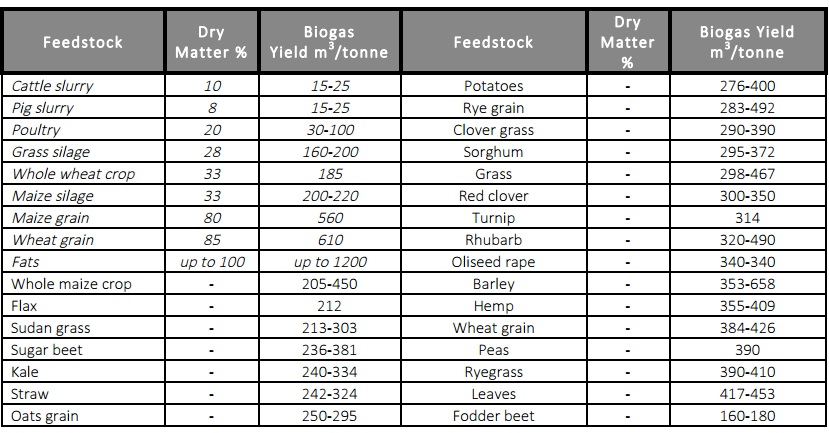

The table below highlights a range of feedstocks and the biogas yields associated with these crops. The table demonstrates the low yield of cattle slurry compared to the comparatively high yield of wheat grain.

There have been university studies that show dry matter yield and methane yield have a strong correlation, however starch and methane yield have no correlation. There are a range of hybrid characteristics when it comes to the yield, for instance the fodder maize can be grown in marginal conditions and only takes 150-160 days to reach the specific grain moisture. The optimum crop ratios can be maximised if the flexibility of local farms allows for specific crops to be grown at the right time in conjunction with neighbouring agricultural land.

16. Operation and Lease

For a usual site with no complications, such as long distance gas connections, unfavourable topography or costly planning challenges to overcome, RAW Biogas (the operating company) will pay the landowner an annual Lease for the life of the plant of 2.5% of the total plant annual turnover, or £80,000 base rent, whichever is the greater. RAW Biogas has forecasted a turnover of £4,000,000 per annum (subsidies increasing with RPI) based on the above feedstocks and current RHI. The plant will be equivalent to just under 2MW in size and provide an expected output into the gas grid of 450scmh (standard cubic metres per hour). The turnover will be based on the quantity of gas that is sold, alongside the various government subsidies.

17. Output quantification & Utilisation

Potential generation from the identified feedstock includes:

• Bio-methane gas export of around 3,500,000 m3 per annum.

• Circa 40,000 tonnes of digestate, depending on breakdown of inputs.

• 42,000 MWh of energy produced.

The creation of these outputs provides clear revenue opportunities in terms of gas export tariffs through grid export and the RHI. The AD plant will benefit investors, the landowner, local employment and the environment.

18. Financial Benefits Explained and the Latest on Tariffs

There are two main financial income streams on a Gas to Grid installation:

• The sale of the gas or electricity locally or to the grid and secondly the government incentives.

• The sale of the gas into to the grid will be recorded through a meter and sold to a gas supplier.

The tariffs that are currently available for a RAW Biogas AD site are gained through the ROO-FIT scheme which is applied for through Ofgem (Office for Gas and Electricity Markets). The application will be submitted and monitored by Raw Biogas. Recent news from Government states a 5% drop in the tariffs (from 7.6p/kWh) for the quarter following the 1st July 2015. This is manageable within the project economics and good news for new developments; but only highlights the need to progress with schemes swiftly in order to maximise the benefits as these degressions occur quarterly. If you have any further questions or would like to discuss a potential scheme, please contact us